When speaking with clients and other industry professionals there seems to be a common trend; the work is good and firms are busy! Great projects are being built, while new and increasingly complex projects are making their way into design. Owners and developers are continually pushing the design team to produce a one-of-a-kind building faster and more economical than the one before. As engineers, we embrace the challenge and are always looking for new and innovative ways to improve the way we work. We create highly sophisticated models that assist in cross discipline coordination and utilize parametric software to automate the modeling process, increasing both quality and efficiency. These efficiencies will continue to increase, and reduce the time it takes the design team to produce a set of construction documents and start building. But what about the way those drawings are brought to life? Although we can produce construction drawings faster, the time it takes to actually “build” has remained constant for the past 30 or so years. This was one of the main talking points at this year’s International Mass Timber Conference.

- #forestproud – This was the motto for the conference. The idea that we are able to create warm, inviting spaces in an innovative way while reducing our carbon footprint is something to embrace and be proud of! Biomimicry and Biophilic design seem to be surging trends in todays architecture.

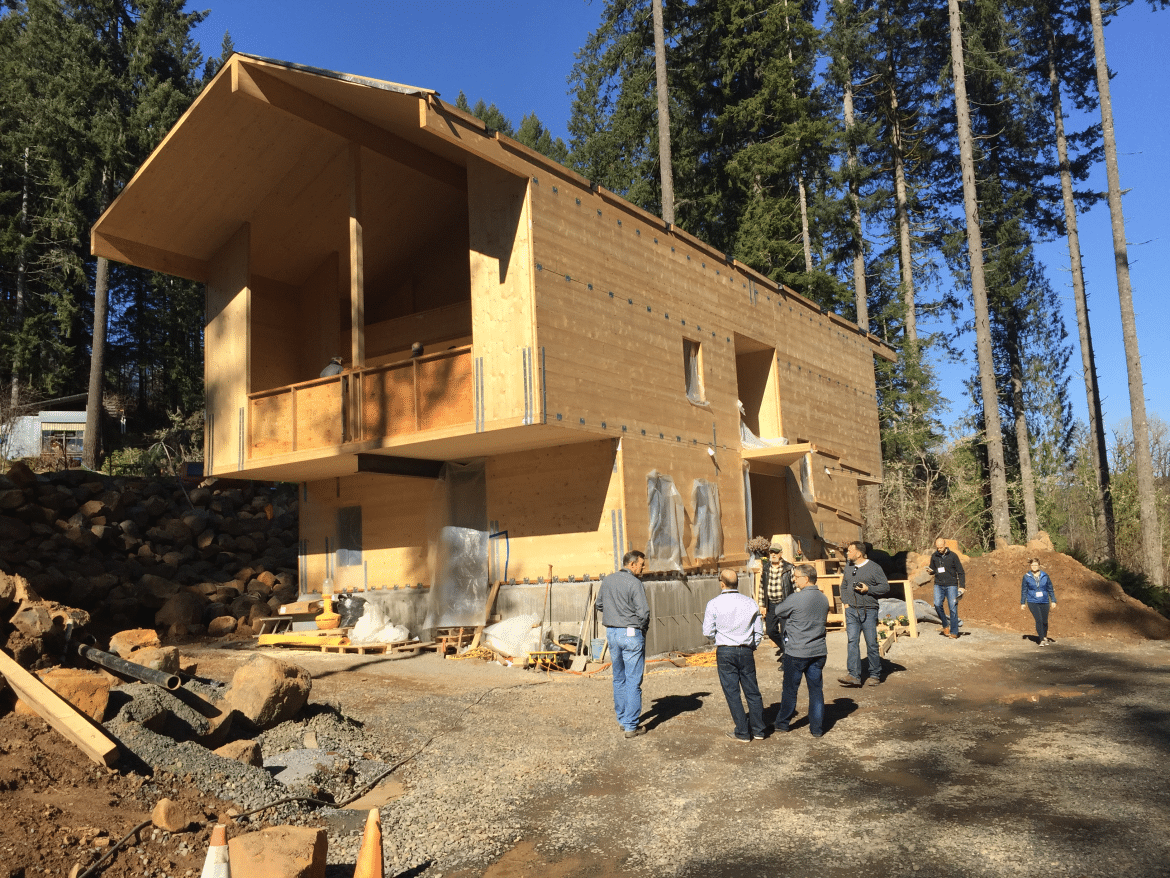

- It’s not an apples to apples comparison – One of the first questions that is always asked when a mass timber system is, how much does it cost? Although mass timber is wood, when comparing cost to conventional wood framing (or even steel and concrete) you should not look at the raw material costs alone. Yes, there is a premium when looking at the costs of CLT panels or glulam columns and beams, but the savings comes with the time that is saved during construction, the simplified inspections, fewer laborers, and foundation savings due to the lighter structure.

- It takes a village – With mass timber still in its infancy, it’s critical to have continual collaboration between not only the design team and owner, but also the product supplier. Early involvement of the timber supplier helps ensure that your design and construction process is as economical as possible.

- Hybrid systems are sometimes best – To use mass timber you do not need to stick with a 100% mass timber system. Sometimes it will make more sense to utilize steel and or concrete in conjunction with mass timber.

- Check your vibrations – the strength of cross-laminated timber (CLT) or nail laminated timber (NLT) floor systems typically does not control the design. Manufactures readily supply design tables that include load, deflection and vibration checks that provide a good baseline design, but the structural engineer should not stop there. The stiffness of the supporting frame needs to be accounted for and global vibrations for the structure should be checked. It is common to provide a concrete topping slab to the mass timber floor, which will enhance vibration and acoustic performance.

- Have it both ways – with the cross laminations in CLT panels, strength can be achieved in both axes of the panel making floor overhangs and balconies less troublesome than conventional framing. Utilizing the ability to cantilever the CLT panels allows for thinner floor depths and eliminates the need for headers at the windows, allowing architects to provide floor to floor windows and really light up a space.

For more information on Mass Timber, please feel free to reach out to Taylor Landry at tlandry@pesengineers.com.

About the author: